rockwell hardness test in hindi|virtual hardness lab : tv shopping Get access to the latest Rockwell Hardness Test (in Hindi) prepared with GATE & ESE course curated by Rahul Choubey on Unacademy to prepare for the toughest competitive exam.

WEB28 de jun. de 2023 · Back in the bad old days of 1944, with the Third Reich beginning to crumble, intrepid young spy Indiana Jones is captured by the fiendish Nazis along with his pal, Professor Basil Shaw, in which .

{plog:ftitle_list}

web17 de nov. de 2022 · Saiba como clonar celular grátis com aplicativos que funcionam e são seguros, como Mspy, Eyezy, Scannero e outros. Veja as vantagens, desvantagens e preços de cada opção e escolha a melhor para você.

What is hardness?Hardness Testing MethodsRockwell hardness test procedureAdvantages

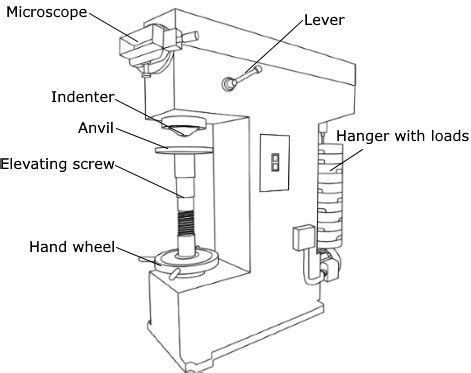

Rockwell hardness test in Hindi. Vishu Dhiman. 5.57K subscribers. Subscribed. 584. 58K views 6 years ago Material and metallurgy. Hello friends in this video we will learn about Rockwell. what is brinell hardness test, brinell hardness test, brinell hardness test in hindi👉Material science and engineering के Pdf Notes के लिए इस वीडियो को .Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied . रॉकवेल कठोरता परिक्षण: रॉकवेल कठोरता परीक्षक भारों की किस्मों के साथ संयोजन में दंतुरित की संख्या का प्रयोग करता है।. इसमें 1/16, 1/8, 1/4, 1/2 .

Get access to the latest Rockwell Hardness Test (in Hindi) prepared with GATE & ESE course curated by Rahul Choubey on Unacademy to prepare for the toughest competitive exam.Get access to the latest Hardness Test (in Hindi) prepared with GATE & ESE course curated by Mrityunjay Saini on Unacademy to prepare for the toughest competitive exam.

vlab hardness tester

The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test .Rockwell hardness test meaning in Hindi (हिन्दी मे मीनिंग ) is रॉकवेल कठोरता परीक्षण. ShabdKhoj Hindi to EnglishVarious methods are used to measure the hardness of a material. Brinell hardness and Rockwell hardness are two of the most common methods used for this purpose. In this article, we will discuss these two hardness testing .

The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520 [email protected] The Rockwell hardness test is one of several common indentation hardness tests used today. The initial pressure of the three scales is 98.07N (10kgf), and finally the hardness value is calculated based on the indentation depth. Ruler A uses a spherical cone diamond indenter, and then pressurizes to 588.4N (60kgf); Ruler B uses a steel ball with .Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. .The Rockwell hardness (HR) is then determined from the residual indentation depth, along with a few other factors (see below). In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as .

Rockwell Hardness Test formula. Your testing equipment will provide an accurate calculation of the Rockwell hardness result, but there’s a formula to calculate the depth that’s measured into a Rockwell hardness number, which is: HR=N-(d/s) Where the value of: d is the penetration depth measured from point zero in mm s is either 0.001 mm or .

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of theThe Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.The Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).

Read this article in Hindi to learn about how to test the hardness of engineering materials. किसी मेटेरियल के हार्डनैस मान को चैक करने के लिए निम्नलिखित विधियों का प्रयोग किया जा सकता है: 1. ब्रिनेल विधि (Brinell Method .Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .

The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go far outside from the specified depth of 0.2mm. With a carbide ball, the specified reference depth is .Introduction, Test Procedure, Calculation Formula, Advantages In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm .

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test .

Regular Rockwell hardness test: In this test, a load of 60, 100, or 150 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material. Superficial Rockwell hardness test: In this test, a .the Rockwell hardness test ( scales and hardness range according to Table 1) for metallic materials. NOTE — For certain materials, the hardness range may be narrower than those indicated. 2 REFERENCE The following Indian Standard contains provisions which through reference in this text, constitutes

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.Brinell and Rockwell Hardness Conversion Table Chart. These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship .

Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

Rockwell hardness test sesuai ISO 6508 / ASTM E18. . Dengan bantuan kedalaman lekukan permanen h, Rockwell hardness (HR) kemudian dapat dihitung menurut rumus yang ditentukan dalam standar ISO 6508 dengan mengacu pada skala Rockwell yang diterapkan. Prosedur uji .

The test procedure for the Rockwell hardness test is covered in the standard document ISO 6508 for metallic materials and ISO 2039-2 for plastics. The overall procedure is similar to other indentation tests. The indenter is pressed into the material, loaded for a time interval (dwell time), and unloaded. . rockwell hardness test in hindi,rockwell hardness testrockwell hardness testerrockwell hardness test machinerockwell hardness test processThe Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

what is brinell hardness test, brinell hardness test, brinell hardness test in hindi👉Material science and engineering के Pdf Notes के लिए इस वीडियो को .

virtual hardness test

WEB29 de set. de 2022 · Mr. Stumble here, let's check together the Patch Notes 🗒️. Android/iOS/Steam Release Date 9/29/2022. Game version: 0.41.1. Downtime: N/A.

rockwell hardness test in hindi|virtual hardness lab